Anti-seepage Pond Liner Fabric

Anti-seepage Pond Liner Fabric

Product Information

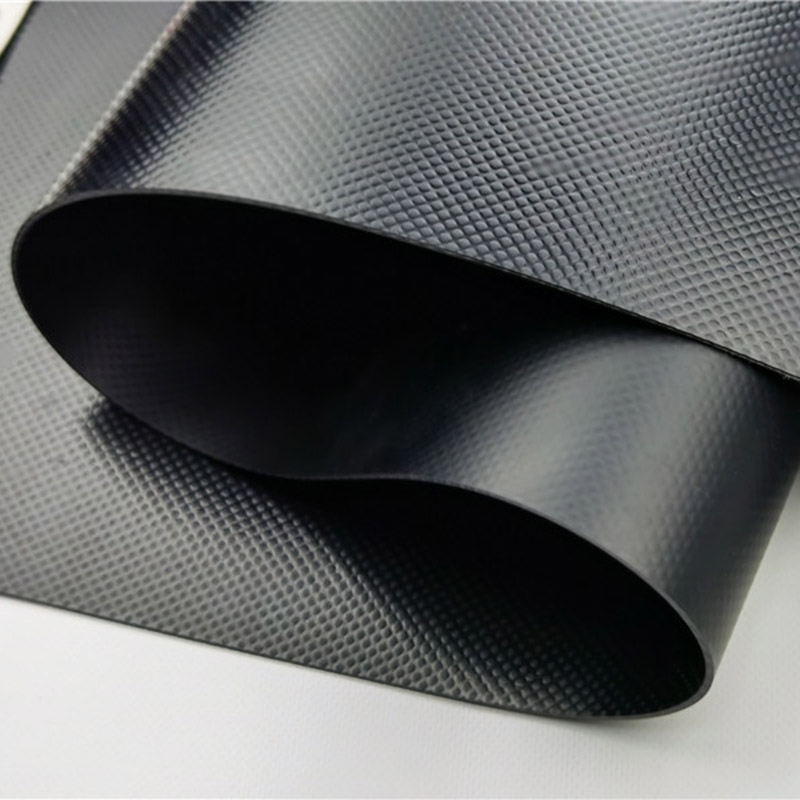

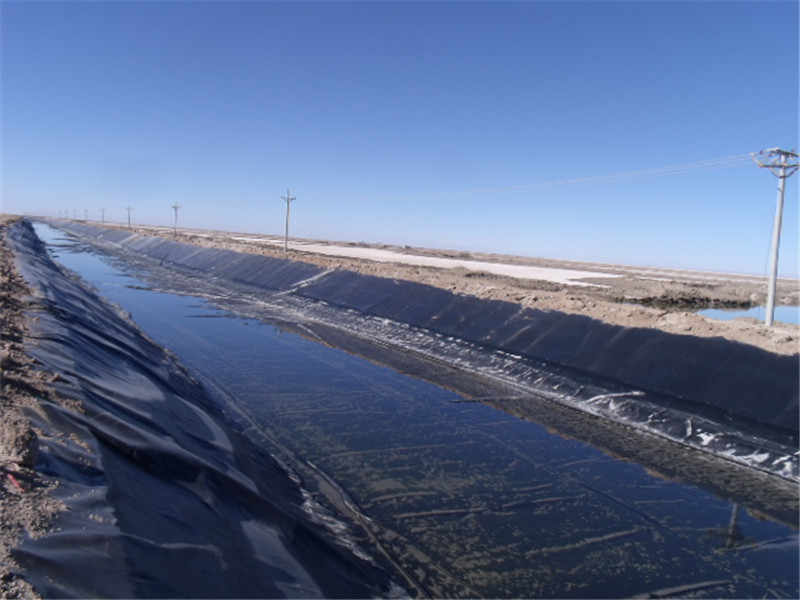

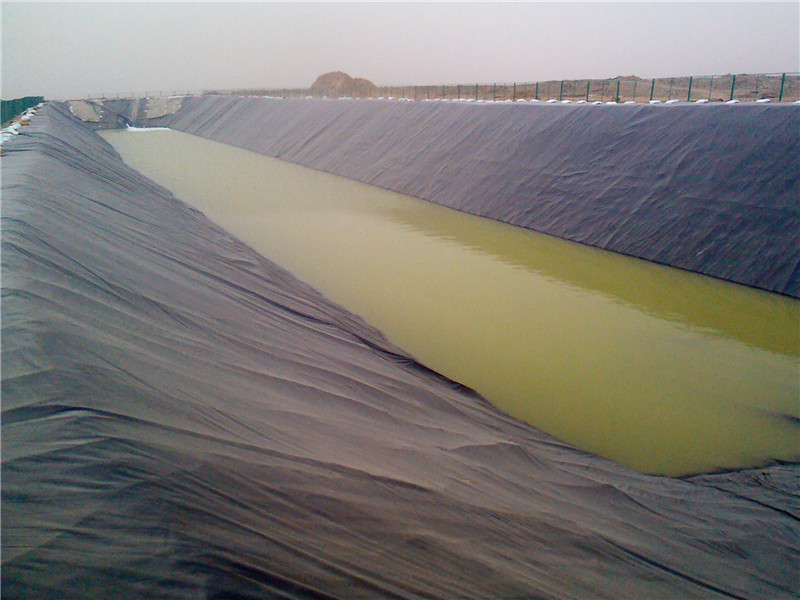

The PVC anti-seepage fabric is made of high-strength polyester fiber with a double-layer PVC coating, which is used for anti-seepage for various purposes, such as ponds, oil drilling, and salt lakes, and has a longer service life than traditional geomembranes and is more wear-resistant.

Product Feature

◈ Corrosion resistance.

◈ Lightweight and high in tensile strength.

◈ Anti-wicking material

◈ Fire resistance

◈ Folding resistance

◈ All characters are available in customized versions according to different environments of use.

Product Advantage

The material is designed as a five-layer structure based on the application background and design requirements of the project:

The first layer is special skeleton material.

Using special skeleton material, the skeleton material uses special fiber material as the skeleton of the channel cloth. The fiber has the following characteristics:

1. High modulus, extremely low shrinkage

2. Eexcellent corrosion resistance;

3. Weight, high strength, equivalent to the strength of steel wire in the same section, but only 1/7 the weight of steel pipe;

4. Anti-wicking, which effectively prevents water from penetrating the material and causing damage to it.

5. High folding resistance.

The use of a special woven structure solves the longitudinal linear shrinkage of the material, which becomes the volume expansion in the thickness direction. According to the test of our company, at -25℃, there is no change in size for 25 hours, and at 80℃ for 168 hours, there is no change in geometric size.

Due to the high strength of the skeleton material, it can completely resist the deformation and stress of the surface plastic material.

The second and third layers: the design of the special bonding layer

Adhesive technology is the technology of connecting the surfaces of homogeneous or dissimilar objects together with adhesive. Materials have affinity and form a whole.

The fourth and fifth layers: the design of surface anti-corrosion and friction-resistant materials

1. The introduction of foreign functional anti-ultraviolet materials can greatly reduce the influence of ultraviolet rays on the aging properties of materials. The product strongly absorbs ultraviolet rays (especially the wavelength of 290-400nm) and protects plastics from photo-oxidative degradation caused by ultraviolet radiation, thus greatly prolonging the service life of the product and enhancing the weather resistance and aging resistance of the product.

In order to meet the requirements of plastic aging resistance, our company will add light stabilizers, ultraviolet absorbers, and cold-resistant plasticizers to the formula in order to meet customer requirements.

2. The use of foreign cold-resistant modifiers to change the low-temperature cracking of special leakage materials can prevent the product from becoming brittle under low temperature conditions. It has good weather and cold resistance and keeps the product at -20-50°C. excellent toughness, impact strength, and stress crack resistance.

3. Introduce foreign modified materials to enhance the chemical corrosion resistance of special anti-seepage materials; the main components of brine are: cations Na+, Ca+, Sr2+; anions Cl-, SO42-, Br-, HCO3-, the materials used in our company. Among them, none of the raw materials will react physically or chemically with the components in the brine, and the materials used are all inert.

4. Introduce foreign functional materials to enhance the puncture resistance, wear resistance, flexural resistance, toughening, good compression set, and recovery of special anti-leakage materials, so that the material has the advantages of rubber at the same time. The performance is better than that of rubber.

The use of the above design solutions not only solves the damage to the material by chemical corrosion, but also more cleverly uses the multi-layer structure to solve the deformation and puncture resistance of the material. The design solves the deformation problem of the material temperature alternating so that the welding seam failure of the material is satisfactorily solved. The above design principles have been proven in practice to be feasible and highly adaptable. The characteristics of this product are organically combined with the unique properties of various materials to form a special anti-seepage composite material. All five-layer structures are formed by the high-temperature hot-melt method to form a whole. Although the product is eventually formed as a whole, each functional layer has its own division of labor and role, forming an overall synergistic effect to ensure the product's anti-leakage and wear-resistant properties, weather resistance, small deformation, and other properties.