PVC Flexible Water Bladder Bag

PVC Flexible Water Bladder Bag

Product Information

The liquid bag is made of PVC flexible fabric. Liquid bags have high compressive strength and good sealing performance, and are widely used in various industries for production and daily life.

Foresight has more than 15 years of experience in fabric production, with an annual output of more than 5 million square meters. At the same time, we have advanced high-frequency orbital welding machines, C-type welding machines, professional fabric welding technology, finished product processing teams, clean and spacious dust-free workshops, unparalleled processing methods, processing speeds, and delivery capabilities, which provide one-stop services for the production of water bags with stable quality and the processing of finished products for domestic and foreign customers.

Product Parameter

| Water Bag Fabric Technical Specification | ||||||

| Item | Unit | Model | Executive Standard | |||

| ZQ70 | ZQ90 | ZQ120 | SCYY90 | |||

| Base fabric | - | PES | - | |||

| Color | - | Red mud, Blue, Army green, White | - | |||

| Thickness | mm | 0.7 | 0.9 | 1.2 | 0.9 | - |

| Width | mm | 2100 | 2100 | 2100 | 2100 | - |

| Tensile strength (warp/weft) | N/5cm | 2700/2550 | 3500/3400 | 3800/3700 | 4500/4300 | DIN 53354 |

| Tear strength (warp/weft) | N | 350/300 | 450/400 | 550/450 | 420/410 | DIN53363 |

| Adhesion strength | N/5cm | 100 | 100 | 120 | 100 | DIN53357 |

| UV protection | - | Yes | - | |||

| Threshold Temperature | ℃ | -30~70 | DIN EN 1876-2 | |||

| Acid and alkali corrosion resistance | 672h | Appearance | no blistering, cracks, delamination and holes | FZ/T01008-2008 | ||

| Tensile load retention rate | ≥90% | |||||

| Cold resistance (-25℃) | No cracks on the surface | |||||

| The above values are average for reference, allowing 10% tolerance. Customization is acceptable for all given values. | ||||||

Product Feature

◈ Excellent waterproof performance

◈ High and low-temperature stability

◈ Weatherproofing

◈ Flexibility, customized shapes, and dimensions are acceptable

◈ Easy to fold, pack, and transport

◈ Easy installation and simple operation

◈ Environmental protection and no pollution

Product Advantage

Over 15 years of experience in the production of PVC flexible air ventilation ducts and fabric, a strong scientific research team, over 10 engineering and technical staff with professional college degrees, over 30 high-speed rapier looms, three composite production lines with an annual output of more than 10,000 tons of calendered membranes, and three automatic ducting welding production lines with an annual output of more than 15 million square meters of fabric, provide long-term support and services for fans company and large projects at home and abroad.

Advanced high-frequency orbital welding machines, C-type welding machines, professional fabric welding technology, finished product processing teams, and clean, dust-free workshops are all available.

Customized water bag shape and dimension, as well as color, are acceptable.

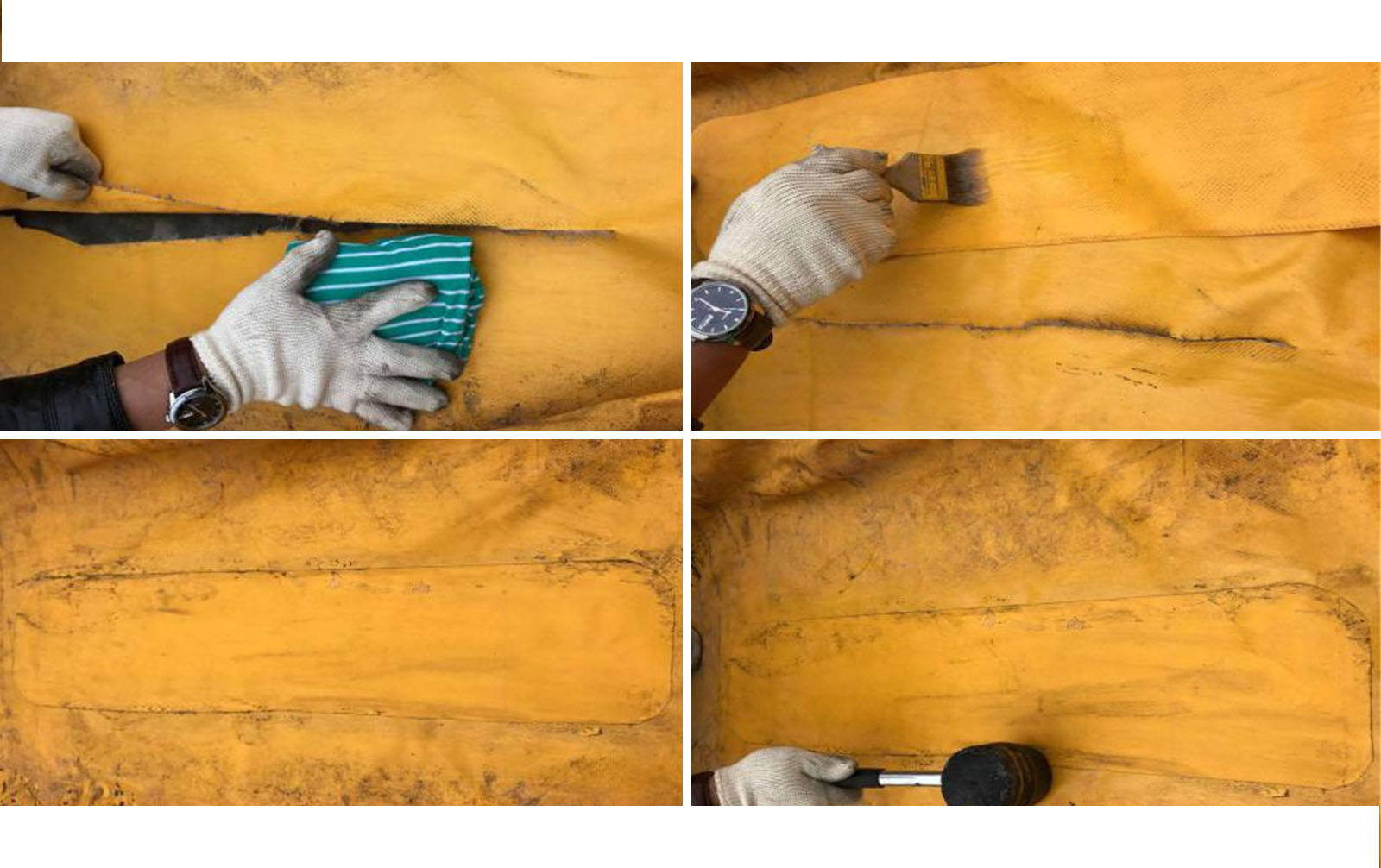

Glue and a portable hot air gun are two versatile repair methods.

Pallet packing will be designed according to the order quantity and the container size, trying to save transportation costs.

Application

Loading test water bag

Biogas fermentation bag

Irrigation water storage bag

Rain water collection bag