JULI® Tunnel/Mine Ventilation Ducting Fabric

JULI® Tunnel/Mine Ventilation Ducting Fabric

Product Information

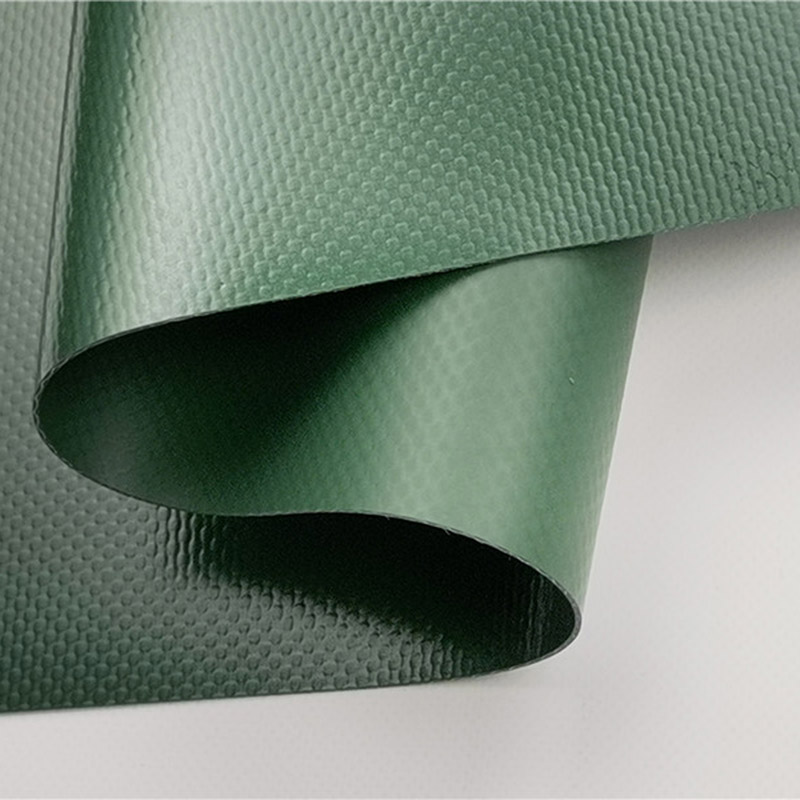

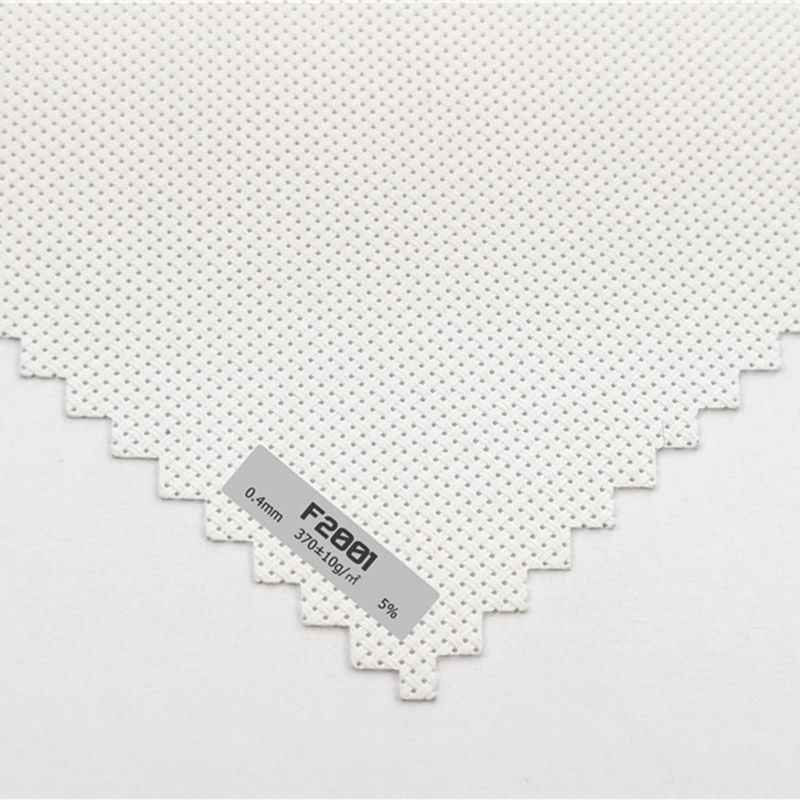

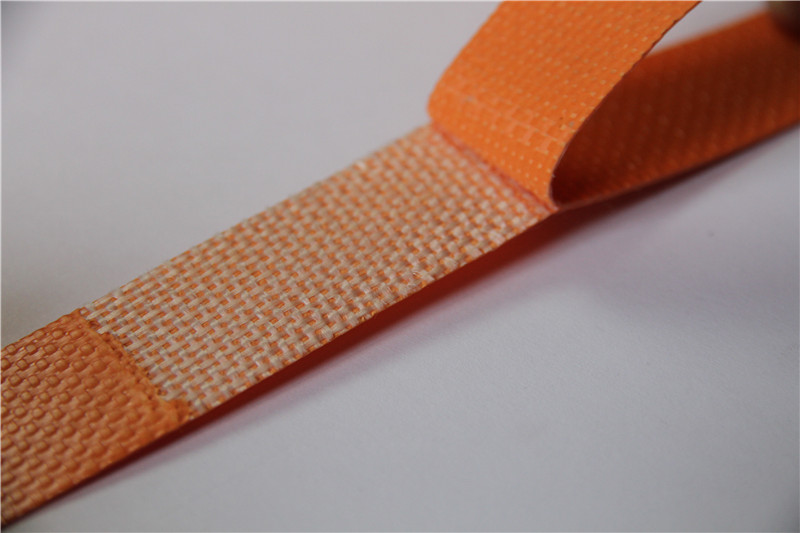

JULI® Tunnel/Mine Ventilation Ducting Fabric is made by polyester fabric as skeleton and PVC coating on both sides, the base fabric can be customized according to customer’s different requirements and using environment, Foresight conducts independent research and development of high-quality PVC flexible ventilation duct membrane compositions that can be modified according to season, application, and performance to provide product quality stability, cost-effectiveness, extended service life, and environmental adaptability.

With great flexibility, the fire resistance, antistatic, and cold resistance can also be customized according to the actual conditions with great flexibility.

Product Parameters

| Tunnel mine ventilaton duct fabric technical specification | |||||||

| Item | Unit | SDCJ2091 | SDCJ13209 | SDCJ13159 | SDC1015 | SDC8410 | Excutive Standard |

| Base fabric | - | PES | - | ||||

| Titer of yarn | D | 2000*2000 | 1300*2000 | 1300*1500 | 1000*1500 | 840*1000 | DIN EN ISO 2060 |

| Color | - | Yellow/Black | Yellow/Black | Yellow/Black | Yellow/Black | Yellow/Black | - |

| Weave Style | - | Knitted fabric | Knitted fabric | Knitted fabric | Woven fabric | Woven fabric | DIN ISO 934 |

| Total weight | g/m2 | 700±30 | 600±30 | 550±30 | 550±30 | 500±30 | DIN EN ISO 2286-2 |

| Tensile Strength (Warp/Weft) |

N/5cm | 2700/2700 | 2400/2400 | 1800/1800 | 2200/2300 | 1700/1800 | DIN 53354 |

| Tear strength (Warp/Weft) |

N | 600/600 | 500/500 | 400/400 | 350/400 | 300/350 | DIN53363 |

| Adhesion strength | N/5cm | 80 | 80 | 70 | 60 | 60 | DIN53357 |

| Threshold Temperature |

℃ | -30~+70 | -30~+70 | -30~+70 | -30~+70 | -30~+70 | DIN EN 1876-2 |

| Fire resistance | - | DIN4102 B1/EN13501/NFPA701/MSHA/DIN75200 | DIN4102 B1/EN13501/NFPA701/DIN75200 | ||||

| Oxygen Index | % | 30 | BB/T0037-2012 | ||||

| Antistatic | Ω | ≤3*108 | |||||

| Maximum working pressure of the duct with safety factor 6(Kpa) | Diameter(mm) | SDCJ2091 | SDCJ13209 | SDCJ13159 | SDC1015 | SDC8410 | Remark |

| 400 | 36.0 | 32.0 | 24.0 | 29.3 | 22.7 | ||

| 500 | 28.8 | 25.6 | 19.2 | 23.5 | 18.1 | ||

| 600 | 24.0 | 21.3 | 16.0 | 19.6 | 15.1 | ||

| 800 | 18.0 | 16 | 12.0 | 14.7 | 11.3 | ||

| 1000 | 14.4 | 12.8 | 9.6 | 11.7 | 9.1 | ||

| 1200 | 12.0 | 10.7 | 8.0 | 9.8 | 7.6 | ||

| 1400 | 10.3 | 9.1 | 6.9 | 8.4 | 6.5 | ||

| 1500 | 9.6 | 8.5 | 6.4 | 7.8 | 6.0 | ||

| 1600 | 9.0 | 8.0 | 6.0 | 7.3 | 5.7 | ||

| 1800 | 8.0 | 7.1 | 5.3 | 6.5 | 5.0 | ||

| 2000 | 7.2 | 6.4 | 4.8 | 5.9 | 4.5 | ||

| 2200 | 6.5 | 5.8 | 4.4 | 5.3 | 4.1 | ||

| 2400 | 6.0 | 5.3 | 4.0 | 4.9 | 3.8 | ||

| 2500 | 5.8 | 5.1 | 3.8 | 4.7 | 3.6 | ||

| 2600 | 5.5 | 4.9 | 3.7 | 4.5 | 3.5 | ||

| 2800 | 5.1 | 4.6 | 3.4 | 4.2 | 3.2 | ||

| 3000 | 4.8 | 4.3 | 3.2 | 4.0 | 3.0 | ||

| The above values are average for reference, allowing 10% tolerance. Customization is acceptable for all given values. | |||||||

Product Feature

◈ High fortitude

◈ High pressure resistance

◈ Excellent tear resistance

◈ Fire resistance

◈ Antistatic

◈ Long life span

◈ All characters are available in customized versions according to the different user environments.

Product Advantage

Foresight has more than 15 years of experience in the production of red mud biogas fabric, a strong scientific research team, more than ten engineering and technical personnel graduated from professional colleges, and more than 30 high-speed rapier looms to meet various needs. with an annual output of more than 10,000 tons of various types of calendered films and an annual output of more than 15 million square meters of fabrics.

From raw materials such as fiber and resin powder to PVC flexible fabric, Foresight has a complete industrial chain.The system has obvious advantages. The production process is controlled layer by layer and comprehensively balances all key indicators, which can be customized according to the customer’s requirements in different environments. We are committed to providing users with the safest and most cost-effective solutions.

To ensure that the JULI® tunnel/mine ventilation duct has excellent physical and mechanical properties, use a high modulus, high strength, low shrinkage polyester fiber as the base fabric.

Use high-quality raw materials to ensure that the JULI® tunnel/mine ventilation is environmentally friendly and has no odor, wear resistance, weather resistance, or folding resistance. The self-developed heat medium oil high temperature and high-pressure composite equipment are used to fit the fabric to ensure that the tensile strength, tear-resistance, and adhesion fastness of the fabric of the Juli tunnel air duct are highly balanced, the surface of the fabric is smooth, and the fabric is easy to unwind.