In the process of tunnel excavation, in order to dilute and discharge the gun smoke, dust, toxic and harmful gases produced by blasting, and maintain good working conditions, it is necessary to ventilate the tunnel excavation face or other working surfaces (that is, send fresh air). But at present, in tunnel excavation construction, the selection and matching of ventilation machinery and equipment, and the control of air volume and wind speed are mostly based on experience. This article briefly introduces how to determine the ventilation air volume and select equipment in tunnel excavation construction.

1. Ventilation and its application

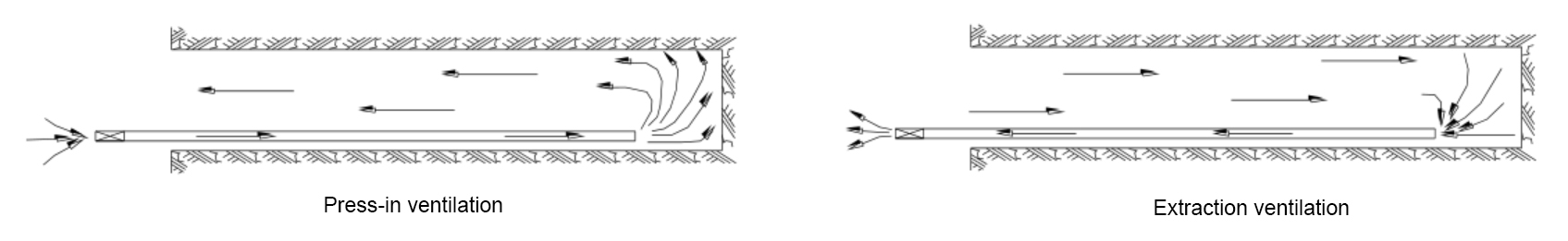

The ventilation mode is determined according to the length of the tunnel, construction method and equipment conditions, and is divided into two types: natural ventilation and mechanical ventilation. Natural ventilation is to use the atmospheric pressure difference between inside and outside the tunnel for ventilation without mechanical equipment; ). Two basic modes of mechanical ventilation (press-in ventilation and extraction ventilation) are shown in the basic ventilation mode diagram for tunnel construction (Figure 1); mixed ventilation is the combination of the two basic ventilation modes, which are divided into long-pressure and short-extraction, long-pressure and long-pressure ventilation. Short-pressing type (front-pressing and back-pressing type, front-pressing and back-pressing type). The applicability and advantages and disadvantages of each are as follows (see Table 1).

Table 1 Applicability and comparison of advantages and disadvantages of commonly used ventilation methods in tunnel construction

|

Ventilation |

Applicable tunnel type | Comparison of advantages and disadvantages | ||

| Natural ventilation | Tunnels with a length of less than 300 meters and no harmful gas generated by the rock formations they pass through or tunnel holing-through ventilation. | Advantages: no mechanical equipment, no energy consumption, no investment. Disadvantages: only suitable for short tunnels or tunnel holing-through ventilation. |

||

| Mechanical Ventilation | Press-in ventilation | Suitable for medium and short tunnels | Advantages: The wind speed and effective range at the outlet of the air duct are large, the smoke exhaust ability is strong, the ventilation time of the working face is short, the flexible ventilation duct is mainly used, the cost is low, and it is commonly used in tunnel construction. Disadvantages: The return air flow pollutes the entire tunnel, and the discharge is slow, which worsens the working environment. |

|

| Extraction ventilation | Suitable for medium and short tunnels | Advantages: Dust, toxic and harmful gases are directly inhaled into the fan, and discharged from the tunnel through the fan, without polluting other places, and the air condition and working environment in the tunnel remain good. Disadvantages: The spiral ventilation ducts adopts a flexible layflat ventilation duct with a steel wire skeleton or a rigid air duct , and the cost is high. |

||

| Hybrid ventilation | Long and extra-long tunnels can be used, with a combination of extraction and press-in ventilation | Advantages: Better ventilation. Disadvantages: Two sets of fans and air ducts are required. Other advantages and disadvantages are the same as press-in and extraction ventilation. |

||

Post time: Mar-31-2022