3. Alternative construction ventilation schemes for different construction stages

3.1 Principles of Construction Ventilation Design

3.1.1 According to the ventilation and hygiene standards for tunnel construction in high-altitude areas, and considering the correction coefficient of the air weight rate in the plateau, the air supply standards and equipment capacity of the tunnel face are determined.

3.1.2 According to the section size of the inclined shaft and the long-distance ventilation needs, the diameter of the underground ventilation ducts in the inclined shaft is 1500mm~1800mm.

3.1.3 In order to achieve better energy saving and good effect, try to use bipolar speed regulating axial flow fan. When the required air volume is large, the fan runs at a high speed; when the required air volume is low, the fan can run at a lower speed.

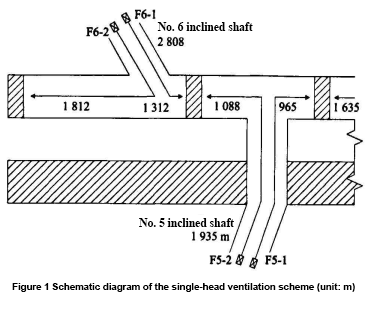

3.2 Incline shaft construction and 2 working face construction ventilation scheme

At this stage, a single-head press-in ventilation is used, as shown in Figure 1. In the system, each working face adopts the pressure into the ventilation mode until through, each inclined shaft support 2 working face construction, each working face adopts 1 underground ventialtion duct, 1 or more fans in series or not in series, according to the actual air volume, wind pressure requirements.

3.3 Research on Ventilation Scheme of Multi-face Construction

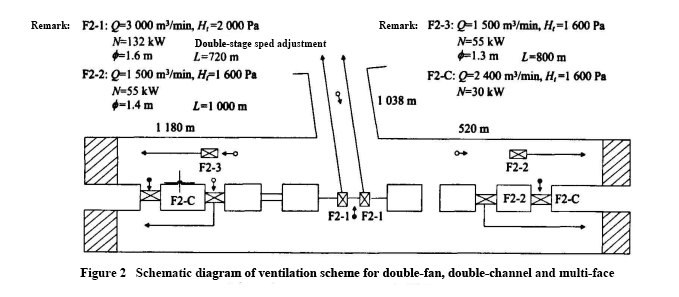

3.3.1 Ventilation scheme of double-fan and double-channel exhaust and pressure-in of each working face

In the construction of extra-long tunnel with multiple auxiliary tunnels, it is common to excavate multiple working faces at the same time. In this scheme, two fans are set at the bottom of inclined shaft to press out dirty air by double channels, and the fresh air enters the tunnel from inclined shaft roadway, and then presses into each working face from local fan. See Figure 2.

3.3.2 Mixed ventilation scheme of inclined shaft bulkhead roadway

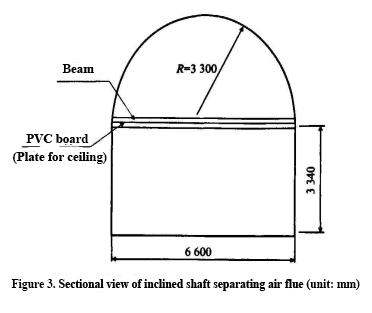

In the study of ventilation scheme, combined with the inclined shaft clearance design, the long inclined shaft is divided into the upper and lower parts of the cross section (height x width 5.2m x 6.6m, the cross area of 31.4m2), the upper radius of 2.6m semicircle, as the fresh air inlet channel, 4 fans are installed at the intersection of the bottom of the inclined shaft and the main hole. The pressurized ventilation system is formed with the tunnel ventilation ducts to supply air to the 4 working faces of line I and Line II respectively. The backflow air is discharged out of the hole through a rectangular passage at the bottom of the inclined shaft (width x height 6.6m x 3.34m)

Figure 3 is the separation diagram of the inclined shaft. The separation board is made of PVC board and sealed with glue; the connection between the separation board and the side wall of the inclined shaft is sealed with a mixture of 107 glue and putty powder or glass glue.

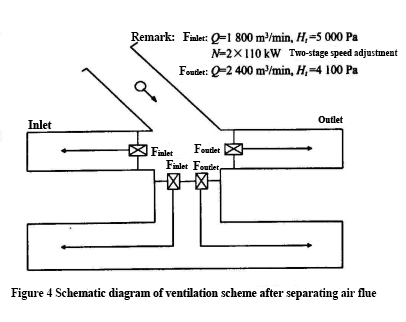

The program has the following advantages:

1. After the separation of the air flue, the air volume increases obviously. After the separation of the air duct, the single-lane inclined shaft can meet the needs of 3 working faces at the same time, and the double-lane inclined shaft can meet the needs of 4 working faces at the same time, which provides the necessary ventilation guarantee for speeding up the construction of guan Jiao tunnel. See Figure 4.

2. The ventilation scheme is simple and can only be divided into two working conditions: shaft construction and main hole construction. Other conditions can be simplified on the basis of this scheme.

3. It ensures that all the air supplied to the face is fresh air, while the disadvantage of other ventilation solutions is pressing in diluted air contaminated by vehicle exhaust during peak transport.

Therefore, inclined shaft plate air flue ventilation is adopted in No.5, No.6, No.8, No.9 and No.10 inclined shaft working area, and tunnel ventilation duct is adopted in other openings.

To be continued…

Post time: Jun-15-2022