Online Exporter Antistatic Ducting - JULI® Spiral Ventilation Ducting – Foresight

Online Exporter Antistatic Ducting - JULI® Spiral Ventilation Ducting – Foresight

Online Exporter Antistatic Ducting - JULI® Spiral Ventilation Ducting – Foresight Detail:

Product Informations

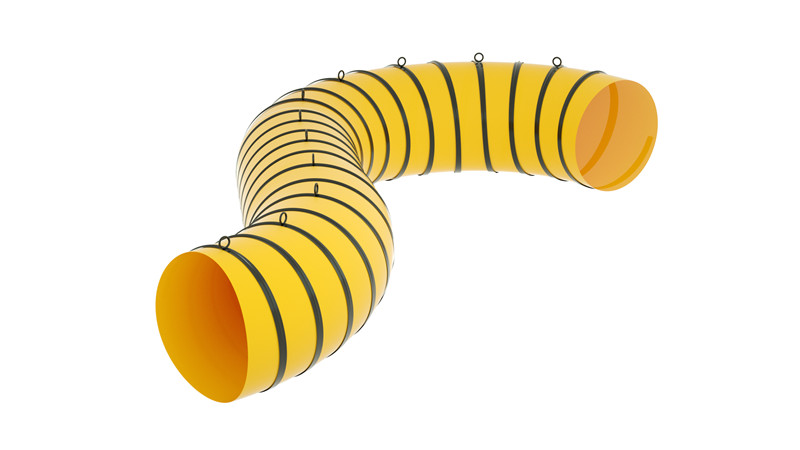

JULI® spiral ventilation duct is made of manganese steel with good elasticity as the reinforced steel wire and can be used under positive pressure for air blowing as an elbow in the underground. It is made by a special welding machine in Foresight with a good appearance and excellent folding performance. During ventilation, the stress is smooth and uniform, and it can bear greater pressure without the danger of blowing. The JULI® spiral ventilation duct can also be used for negative pressure and exhausting air from a tunnel inside. The reinforced steel wire is made of cold-drawn steel, which can support high air extraction pressure to meet the needs of customers.

The fire resistance of the JULI® tunnel ventilation duct is DIN4102 B1, NFPA701, EN13501, DIN75200, and all fire resistance is accompanied by an SGS test result. When a fire is present, a high flame retardant can help to limit the hazardous and harmful gases that can injure the human body.

Product Parameters

| JULI® Spiral Ventilation Ducting Technical Specification | ||

| Item | Unit | Value |

| Diameter | mm | 300-2500 |

| Section length | m | 5, 10 |

| Color | - | Yellow, Orange, Black |

| Suspension | - | Diameter<1800mm, single suspension ring |

| Diameter≥1800mm, double suspension ring | ||

| Suspenion ring spacing | mm | 200-600 |

| Steel ring diameter | mm | 5-10 |

| Standard pitch | mm | 100-300 |

| Sealing face sleeve | mm | 150-250 |

| Coupling | - | Zipper/Velcro/Steel ring/Eyelet |

| Fire resistance | - | DIN4102 B1/EN13501/NFPA701/DIN75200 |

| Antistatic | Ω | ≤3 x 108 |

| Packing | - | Pallet |

| The above values are averages for reference, allowing 10% tolerance. Customization is acceptable for all given values. | ||

Product Feature

◈ Designed for both high negative and positive pressure and elbow use.

◈ Spiral reinforced by spring steel wire/individual steel ring (end ring), seams and PVC profile welded airtight, smooth inner surface, low friction loss.

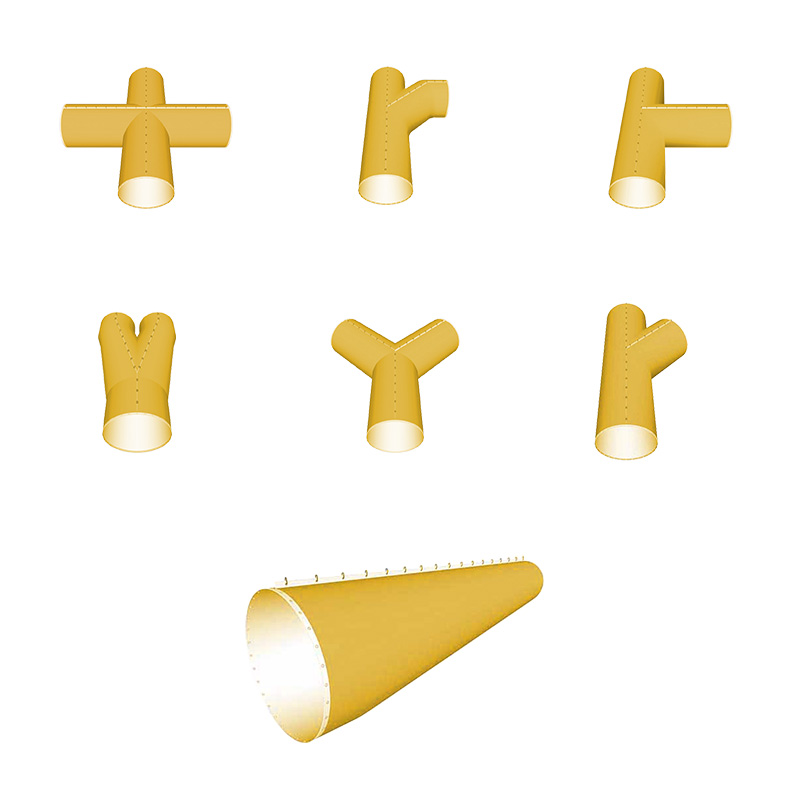

◈ All ducting and fittings are available in an oval shape.

◈ Customization is possible, with a diameter range of 400 mm to 2100 mm.

◈ Flame resistance conforms to EN13501/DIN4102 B1/NFPA701/DIN75200.

◈ Standard length, 5 m, 10 m, 15m or 20m.

◈ The antistatic feature (3×108Ω) is optional. The newly developed water-based material that is used for antistatic surface treatment is an environmentally protective material without VOC emission in processing and use, and is also healthy for workers. It makes the antistatic value stabilize at 3×106Ω.

Product Advantages

Application

Product detail pictures:

Related Product Guide:

All we do is usually connected with our tenet " Customer to start with, Rely on initial, devoting on the food packaging and environmental protection for Online Exporter Antistatic Ducting - JULI® Spiral Ventilation Ducting – Foresight , The product will supply to all over the world, such as: Turkey, Morocco, Georgia, Our staffs are adhering to the "Integrity-based and Interactive Development" spirit, and the tenet of "First-class Quality with Excellent Service". According to the needs of every customer, we give customized & personalised services to help customers achieve their goals successfully. Welcome clients from home and abroad to call and inquire!

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.