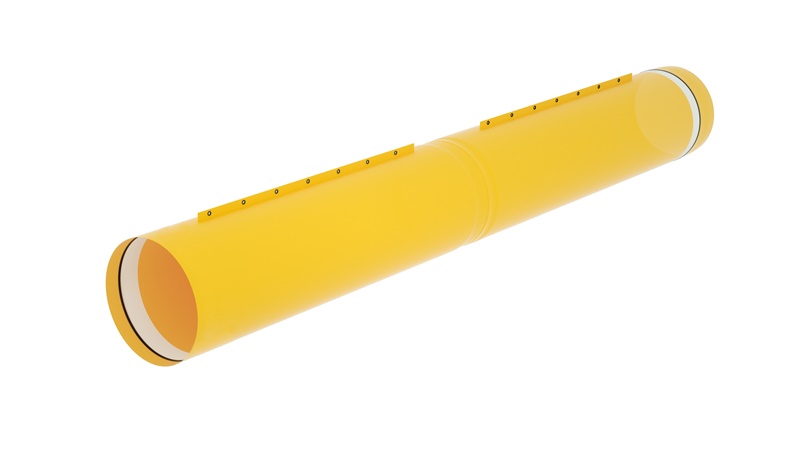

Special Design for Layfalt Ventilation Ducting - JULI® Layflat Ventilation Ducting – Foresight

Special Design for Layfalt Ventilation Ducting - JULI® Layflat Ventilation Ducting – Foresight

Special Design for Layfalt Ventilation Ducting - JULI® Layflat Ventilation Ducting – Foresight Detail:

Product Informations

Foresight conducts independent research and development of high-quality PVC flexible ventilation duct membrane compositions that can be customized based on season, application, and performance to provide product quality stability, cost-effectiveness, extended service life, and environmental adaptability.

The fire resistance of the JULI® tunnel ventilation duct is DIN4102 B1, NFPA701, EN13501, DIN75200, and all fire resistance is accompanied by an SGS test result. When a fire is present, a high flame retardant can help to limit the hazardous and harmful gases that can injure the human body.

The automatic production line independently developed by Foresight can realize the production of duct sections with lengths of 100 m, 200 m, and 300 m, including welding suspension fin/patch, welding duct body, folding, etc., which greatly improves the production efficiency and reduces the air leakage rate of the tunnel ventilation duct.

suspension system

Single suspension fin

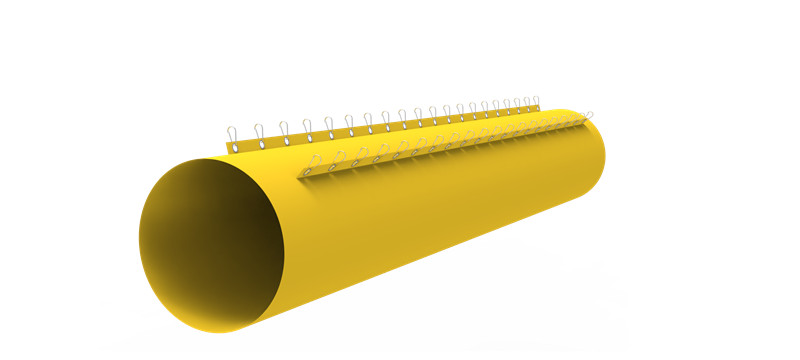

Two suspension fins

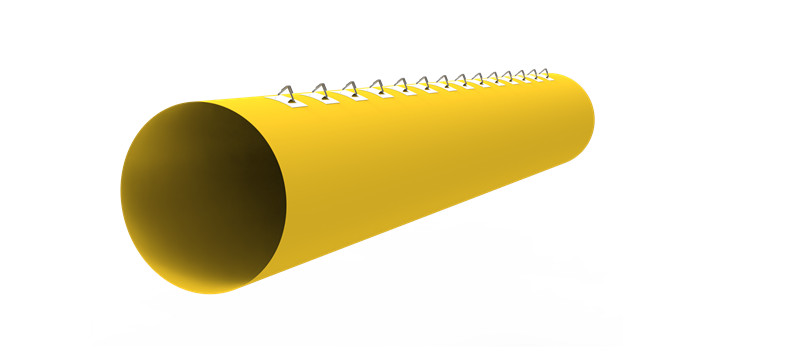

Single suspension patch

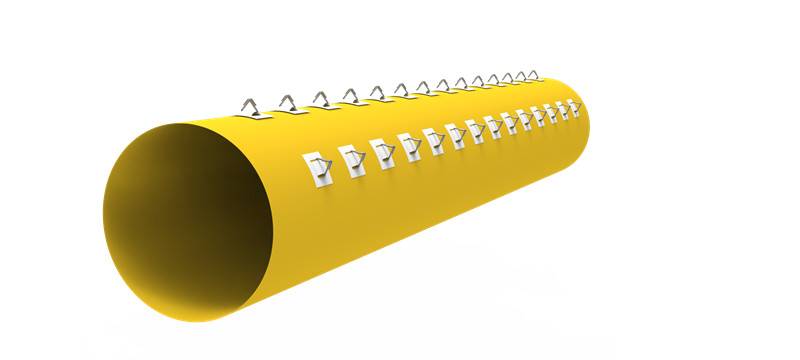

Two suspension patches

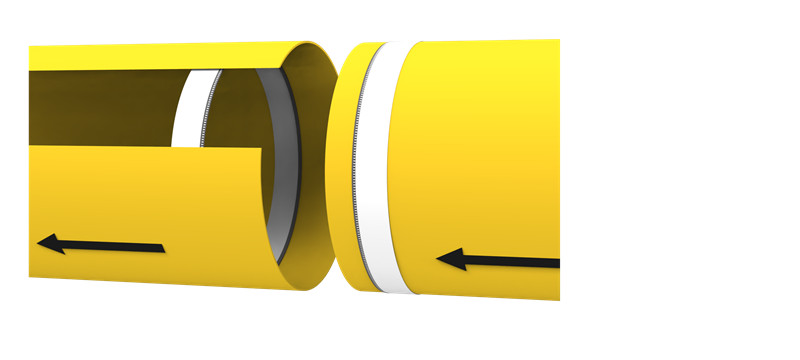

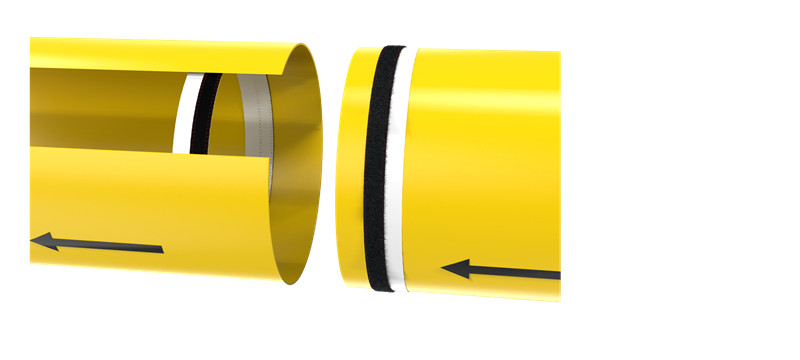

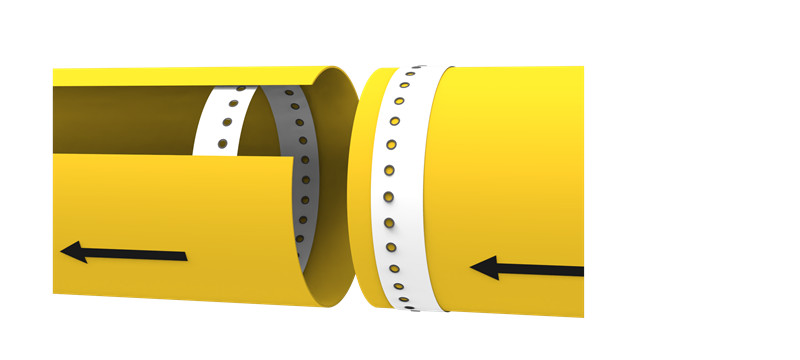

Coupling system

Zipper Coupling

Velcro Coupling

Eyelet Coupling

End ring Coupling

Product Parameters

| JULI® Layflat Ventilation Ducting Technical Specification | ||

| Item | Unit | Value |

| Diameter | mm | 300-3000 |

| Section length | m | 5, 10, 20, 30, 50, 100, 200, 300 |

| Color | - | Yellow, Orange, Black |

| Suspension | - | Diameter<1800mm, single suspension fin/patch |

| Diameter≥1800mm, two suspension fins/patches | ||

| Sealing face sleeve | mm | 150-250 |

| Grommet spacing | mm | 750 |

| Coupling | - | Zipper/Velcro/Steel ring/Eyelet |

| Fire resistance | - | DIN4102 B1/EN13501/NFPA701/DIN75200 |

| Antistatic | Ω | ≤3 x 108 |

| Packing | - | Pallet |

| The above values are averages for reference, allowing 10% tolerance. Customization is acceptable for all given values. | ||

Product Feature

◈ For positive pressure applications, layflat ventilation ducts are ideal.

◈ All ducting and fittings are available in spiral and oval.

◈ Airtight seams and grommets are soldered, resulting in negligible friction loss.

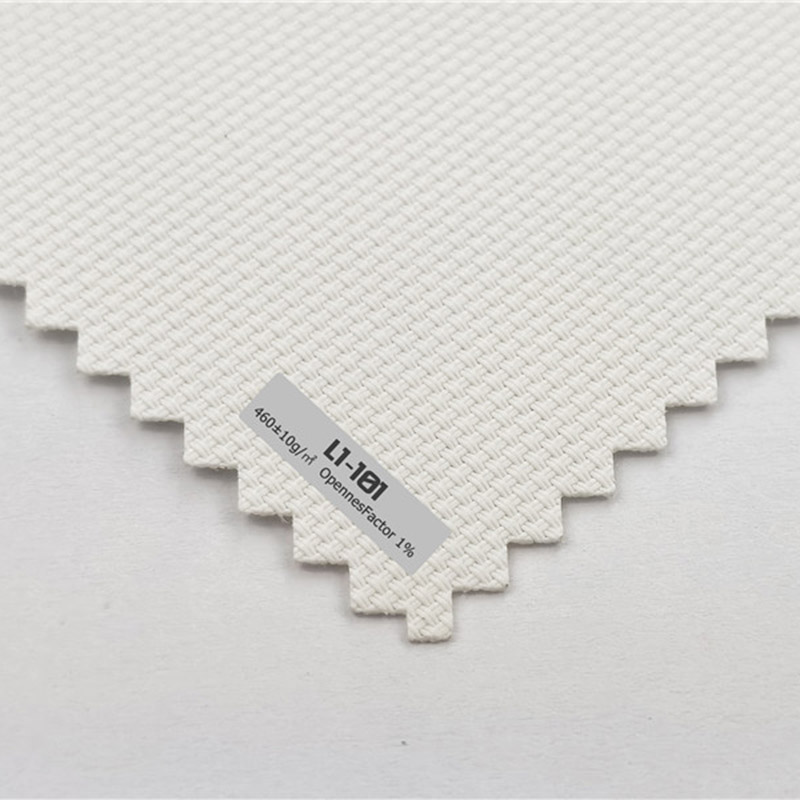

◈ Polyester woven or knit fabric with PVC coating on both sides.

◈ The flame resistance meets DIN4102 B1/EN13501/NFPA701/DIN75200 standards.

◈ Customization is available for diameters ranging from 300 mm to 3000 mm.

◈ Standard lengths of 10 m, 20 m, 50 m, 100 m…developed specifically for TBM. Section lengths can reach 200 m, 300 m, or even longer, and lifetimes can range from 5 to 10 years.

Product Advantages

Application

Product detail pictures:

Related Product Guide:

Bear "Customer initially, High quality first" in mind, we do the job closely with our customers and supply them with efficient and skilled providers for Special Design for Layfalt Ventilation Ducting - JULI® Layflat Ventilation Ducting – Foresight , The product will supply to all over the world, such as: Bolivia, Uganda, Anguilla, Wide selection and fast delivery for you! Our philosophy: Good quality, great service, keep improving. We are looking forward that more and more oversea friends join in our family for further development near the future!

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!